At Gude Packaging Materials Co., Ltd., we take pride in our ability to provide tailor-made plastic packaging solutions that cater to the unique needs and requirements of our customers. With our expertise in gravure printing and extensive knowledge of the packaging industry, we offer a seamless process that delivers personalized packaging solutions from design to delivery. Our custom-made approach allows our customers to have full control over the design and size of their plastic packaging bags. Whether you require a specific shape, size, or style, such food packaging bag as flat square bottom pouch, stand up zipper pouch, side gusset bag and 3 side seal zipper bag, we work closely with you to bring your vision to life. From selecting the perfect material and structural design to incorporating your branding elements, our team of experienced professionals ensures that every detail of your packaging bags aligns with your packaging goals and target audience. One of our key strengths is our ability to provide expert guidance on material structure based on the intended purpose of your packaging. We understand that different products require different levels of protection and barrier properties. Candy bags can be different from Coffee bags. Our team, armed with an in-depth understanding of various packaging materials and their specifications, advises you on the best material choices to ensure optimum product preservation, shelf life, and visual appeal. The process begins with a collaborative consultation, where our experts discuss your packaging requirements and goals. We listen carefully to your ideas, preferences, and brand identity, ensuring that we capture your unique essence in the final design. Once we understand your vision, we can give a complete solution suggestion concerning the bag style and material structure, etc. When the design is finalized and the order is settled, our team applies advanced gravure printing techniques to bring your design to life with stunning clarity and precision. Throughout the production process, our quality assurance team conducts rigorous inspections to ensure that each plastic packaging bag meets our stringent standards of excellence. We not only strive for visually appealing and functional plastic packaging, but also prioritize eco-friendly options by utilizing sustainable materials and embracing eco-conscious practices. Finally, we take care of timely delivery, ensuring that your customized packaging bags reach you seamlessly. Our commitment to efficiency and reliability means you can expect your orders to be fulfilled promptly and accurately, no matter the size or complexity. Partnering with Gude Packaging Materials Co., Ltd. means gaining access to a team of experts dedicated to delivering custom-made plastic packaging solutions tailored to your unique needs. Experience the power of personalization and stand out in the competitive market with excenlent food packaging that captures your brand identity, provides outstanding protection, and leaves a lasting impression on your customers.

1. Choose a Packaging Style.

Commonly used bag style:

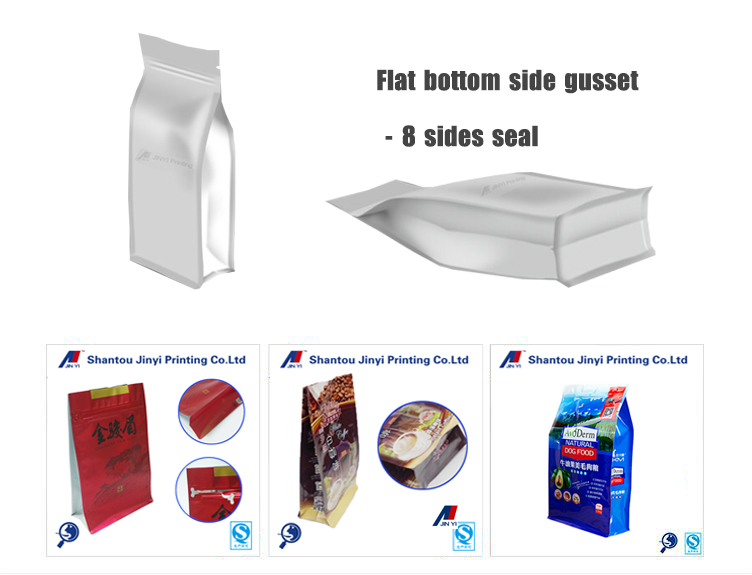

A. Flat bottom gusset bag, Stand up bag, 3 side seal bag, all these 3 bag style can be done with or without a reclosable zipper on the top.

B. Back seal bag, Back Seal bag with gusset, this kind of bag can’t be done with zipper.

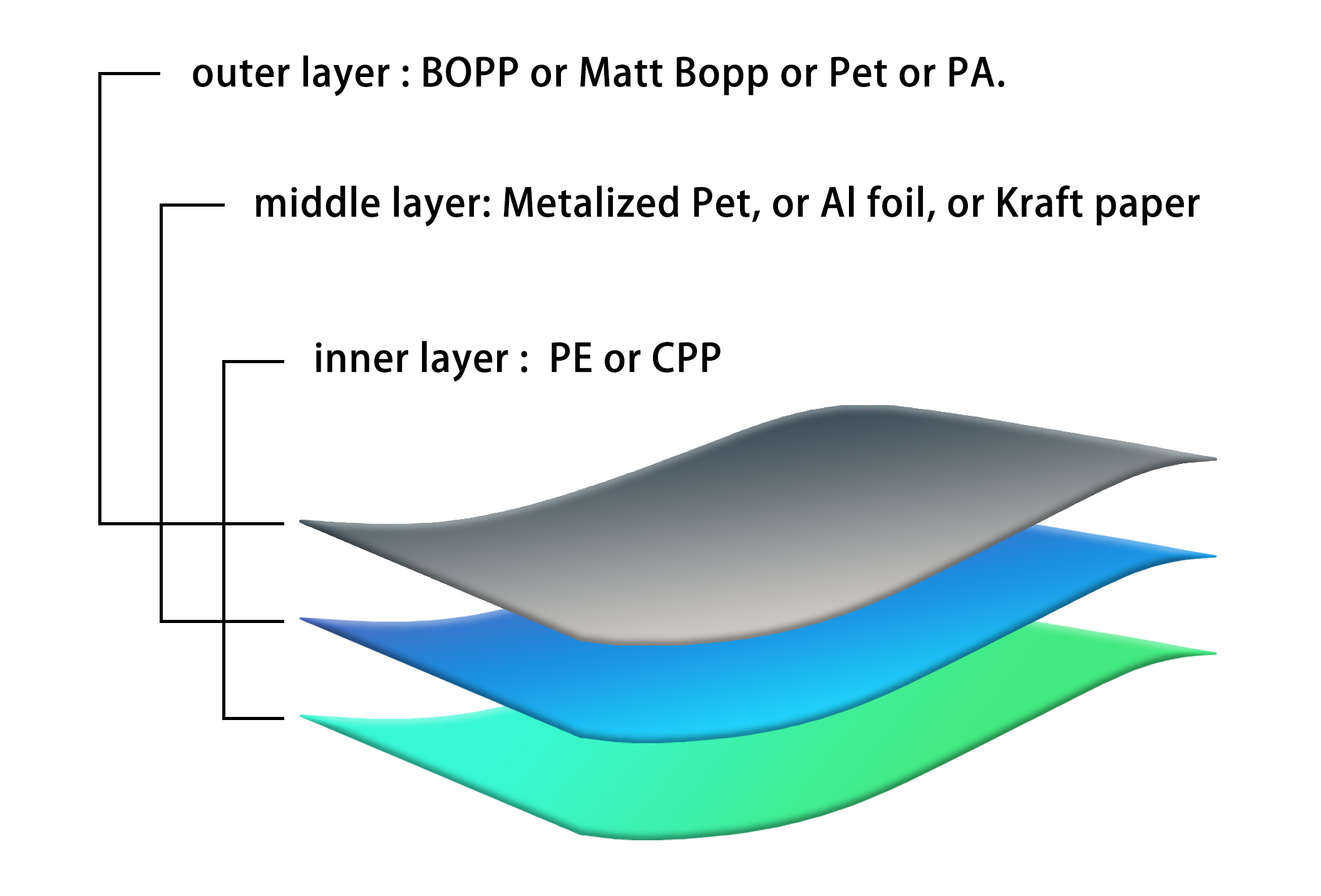

2. Choose the Material Structure

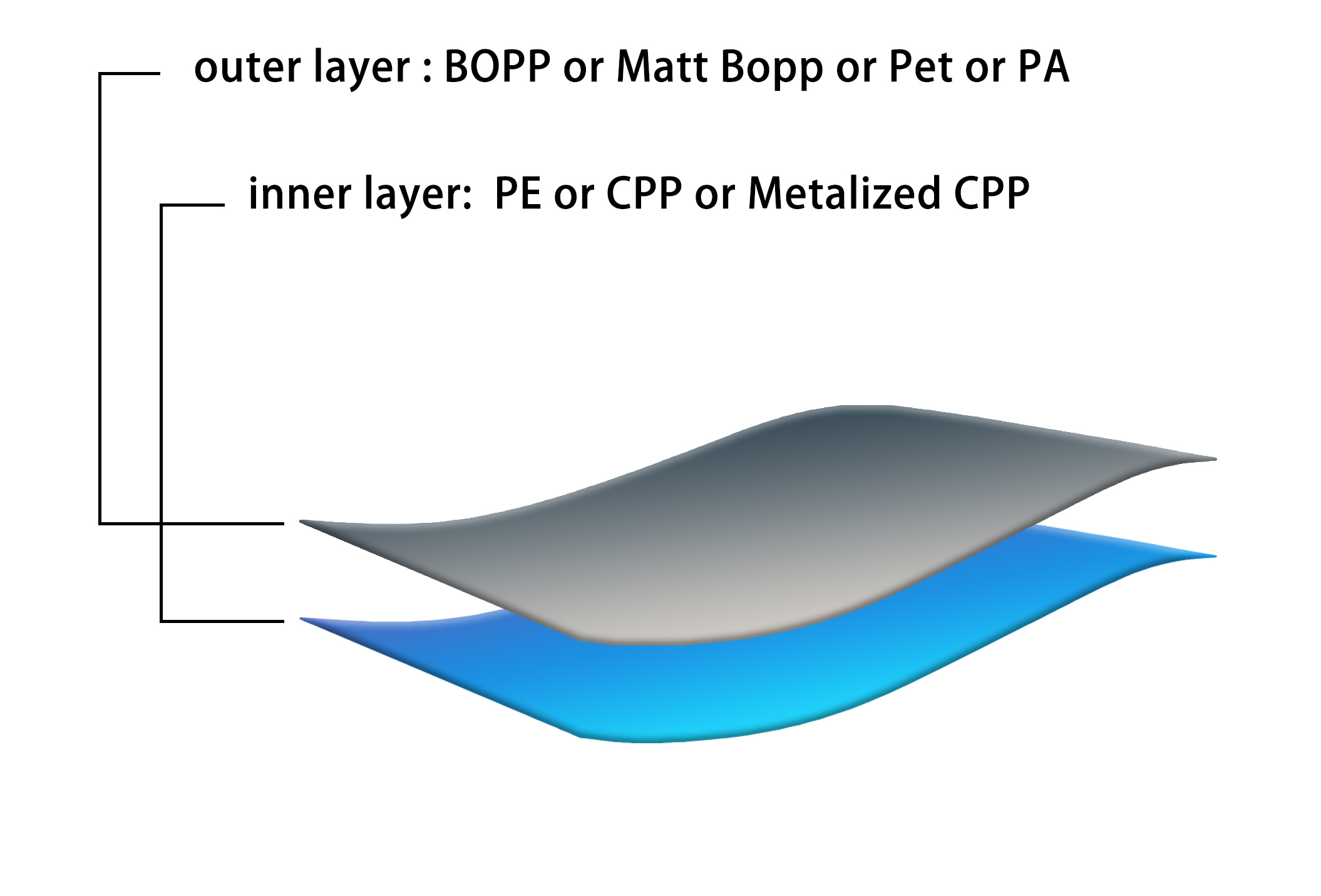

A: 2 layers laminated:

Outer layer can be BOPP or Matt Bopp or Pet or PA;

Inner layer can PE or CPP or Metalized CPP or Metalized BOPP;

B: 3 Layers laminated:

outer layer can be BOPP or Matt Bopp or Pet or PA.

Middle layer can be: Metalized Pet, or Metalized BOPP or Aluminum foil, Kraft paper.

inner layer can PE or CPP.

3. Prepare the artwork for the packaging bag when the bag style and bag dimension are settled.

We need the original artwork in the format of PDF, or AI or PSD for Printing Cylinder Precess.

We will re-arrange the layout of the artwork according to the cylinder operation and send it to you for your further appovals.

4. It takes about 5 days to have the printing cylinder ready, then it will go to printing, laminating, slitting and bag making.

Cylinder Process

Printing

Laminating

Bag-making

Post time: Nov-22-2023